How to Tool a Vibratory Feeder Bowl

Precautions

Some parts are inherently difficult to feed. Lead wires on electronic components, for instance, tend to tangle. Unfired ceramics and unsintered pressed metal parts are very fragile and may be damaged. Parts coated with heavy oils tend to adhere to conventional bowl tracks and must be supported on thin rails.

Some parts are inherently difficult to feed. Lead wires on electronic components, for instance, tend to tangle. Unfired ceramics and unsintered pressed metal parts are very fragile and may be damaged. Parts coated with heavy oils tend to adhere to conventional bowl tracks and must be supported on thin rails.

If you would like to see more examples of feeder tooling, browse our parts feeding tips.

Fortunately, many parts can be classified into one of eight categories according to their configuration and dimensions. Consult the following links for illustrations which show typical vibratory bowl tooling techniques.

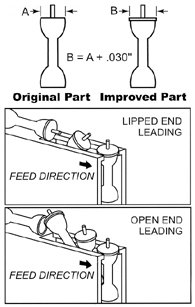

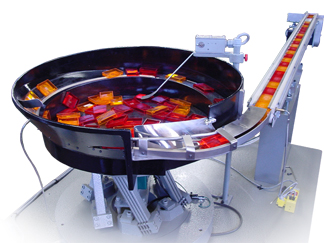

The tooled feeder bowl to the right is in many ways unique, yet the design of the tooling follows a basic plan: size the bowl for the part, use the part's natural orienting characteristics, reduce parts to a single line of feed, design obstructions to yield only oriented parts, and maintain orientation as the parts leave the bowl.

Tooling Principles

Design for Automation

Part Size & Weight

How to Analyze a Part

Orienting Part Shapes

Feeder Tooling Resources