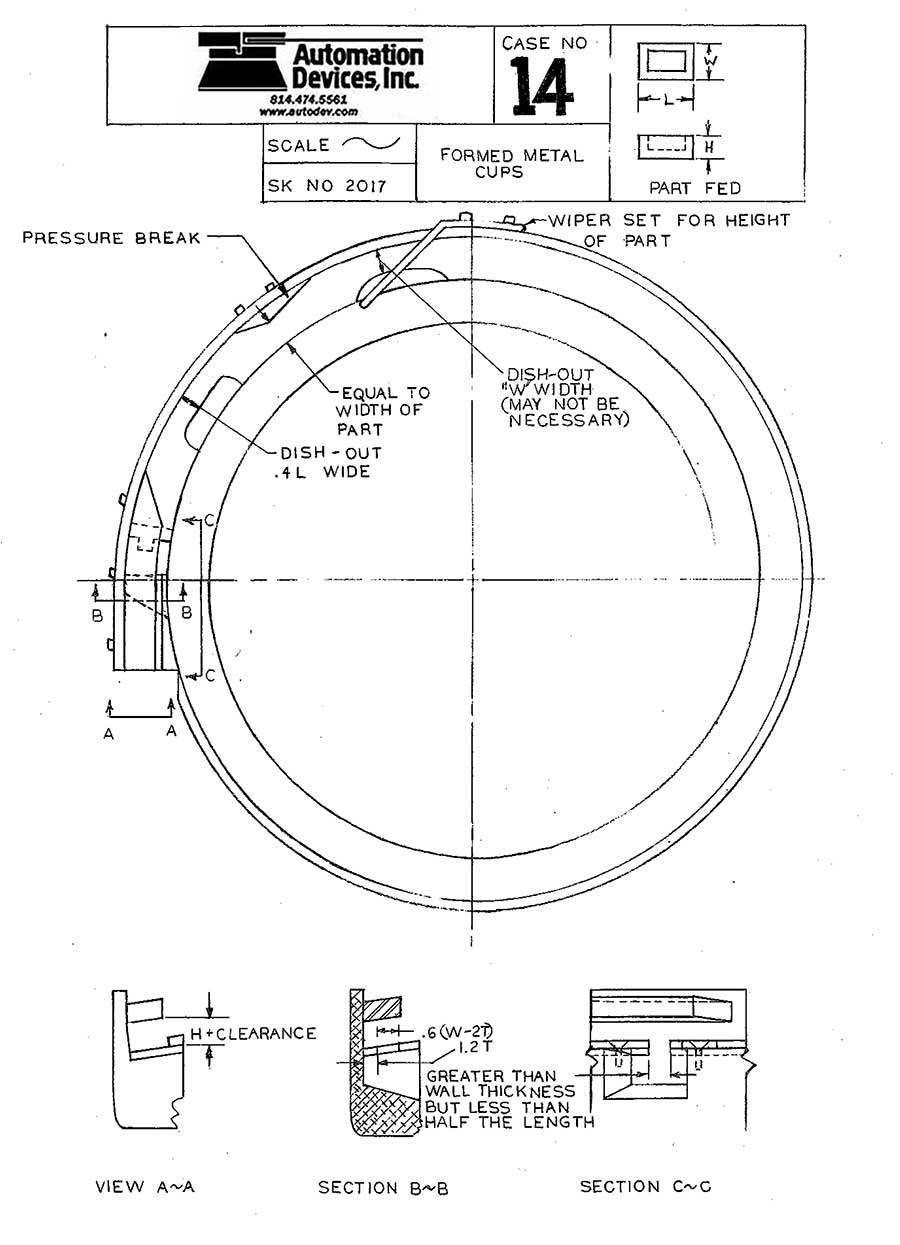

Bowl Tooling Techniques - Case 14

Rectangular Cup or Cap Shaped Parts

(height of part is less than width or length)

End Orientation - Part traveling linearaly end to end, short side leading and trailing, open side up

For use with flat track bowls such as:

8" - CB 151 or CB150 on Model 5 Base Unit

11" - CB 274 or CB 273 on Model 8 Base Unit

18" - CB 154 or CB 152 on Model 10 Base Unit

24" - CB 168 or CB 167 on Model 15 Base Unit

Note: Flat track bowls generally have a 7 degree positive rake to allow parts to find the corner of the track and sidewall of the bowl.

Orientation Sequence

Parts are allowed to travel up the bowl helix randomly until they reach a wiper to clear any parts not lying flat in the low-profile attitude. Parts traveling perpendicular to the line of feed will fall off the track via the spill-off/dish-out machined into the track under the wiper. At this point, the only parts that can continue further are parts traveling linearly end to end but either open side up or open side down. A pressure break is installed to relieve pressure on downstream tooling. Another spill-off/dish-out is machined into the track to reject any parts that possibly became misoriented from the pressure break. A cover is introduced on top of the part, sandwiching the part from misorientation. Under the cover, a pocket is machined, featuring a finger that juts out under the part for the purpose of differentiating an open-side-up part from an open-side-down part. The open-side-up part is carried across the machined pocket being partially supported by the finger and contained by the cover. The open-side-down part hooks over the finger, much like a scallop, allowing the part to pivot down into the pocket and back into the bowl. Only parts traveling linearly end to end, open-side-up can continue.