Bowl Tooling Techniques - Case 16

Convex Lens Shaped Part

End Orientation - Part traveling random diameter to diameter, convex dome either up (centerline axis vertical) or convex dome toward bowl center (centerline horizontal). End orientation is dependent on end tooling at the bowl discharge.

For use with flat track bowls such as:

8" - CB 248 or CB257 on Model 5 Base Unit

11" - CB 340 or CB 341 on Model 8 Base Unit

12" - CB 153 or CB 148 on Model 10 Base Unit

18" - CB 204 or CB 197 on Model 10 Base Unit

24" - CB 249 or CB 251 on Model 15 Base Unit

30" - CB 259 or CB 258 on Model 25 Base Unit

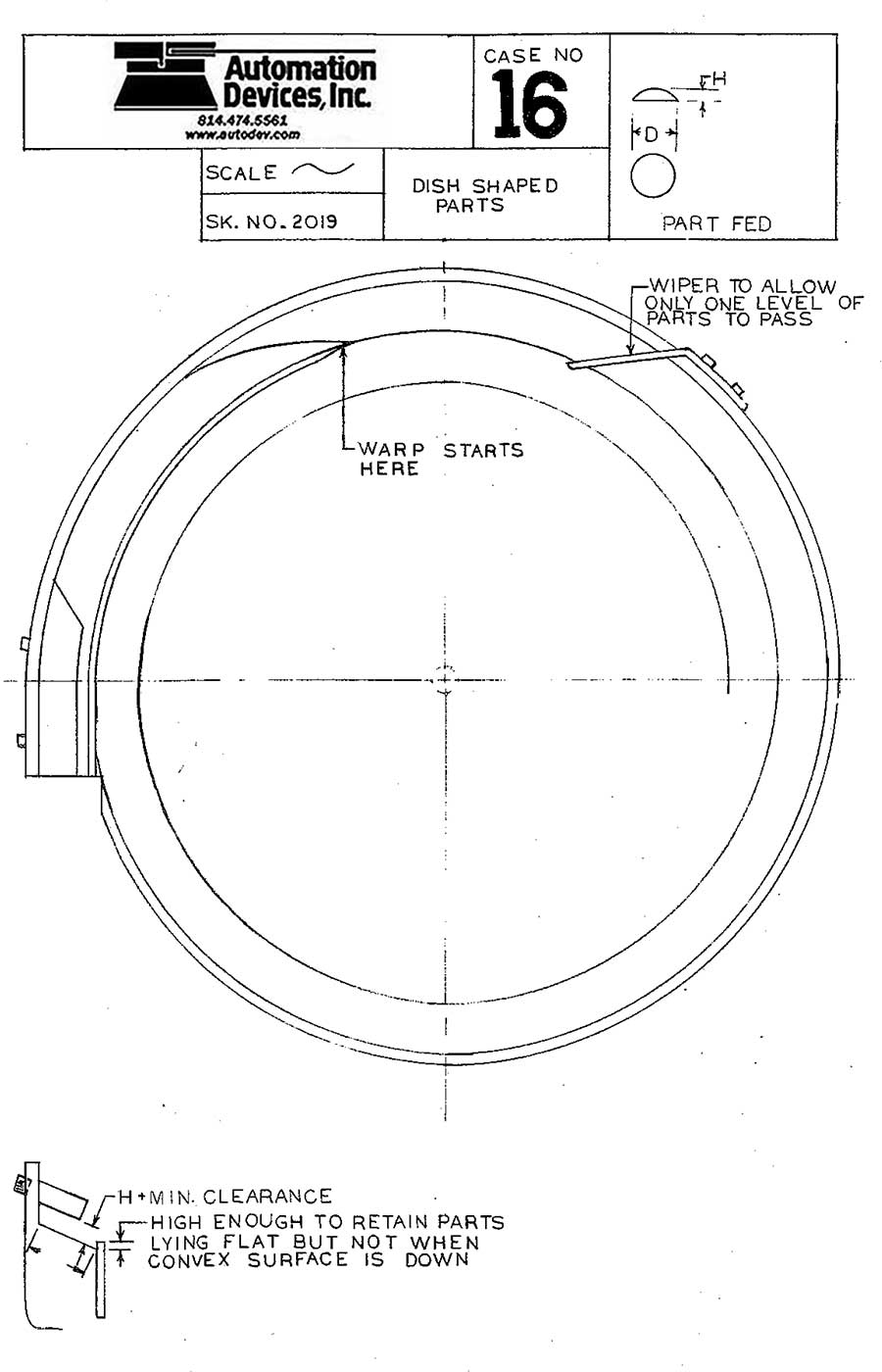

Note: High negative bowls generally start out on a 7-degree positive angle track and warp up to a 60-degree negative angle track that continues to the end discharge of the bowl. This track configuration takes advantage of the point-of-balance of a part through the use of gravity.

Orientation Sequence

Parts are allowed to travel up the bowl helix randomly until they reach a wiper to bring the parts to a single line of feed. This wiper is fabricated to progressively wipe up to prevent parts from wedging underneath the wiper. As the bowl track warps up from a 7-degree positive angle to a 60-degree negative angle in the last two quadrants of the bowl, a rail/curb is installed on the inside edge of the helix floor. This rail catches the part as it changes its path of travel from riding along the outside bowl wall on the 7-degree positive rake to riding along the inside rail once gravity takes over on the 60-degree negative angle. This rail leaves only enough of a curb to catch the sharp edge of the convex lens while the flat back side of the lens mates with the relatively flat surface of the 60-degree bowl track. The part is currently oriented with the convex side towards the bowl center on a 60-degree angle. Misoriented parts (convex side away from bowl center) will slide over the curb and return back into the bowl. If misoriented parts continue to stay on the rail/curb, the rail profile must be reduced until only the correct parts will stay on.

At times, the customer can accept the part to exit the bowl on a 60-degree angle. Other times, the customer will desire the part to be lying flat or in a vertical rolling position. Both end orientations can be achieved in the bowl via additional tooling/tracking that bolts to the bowl beyond the discharge point that will continue to fully contain the part, hold tolerances around the part to prohibit the part from overlapping and smoothly roll the part to vertical or lay the part down to flat.