Vibratory Feeder Bowls

Making the Choice: Cast Aluminum vs. Stainless Steel

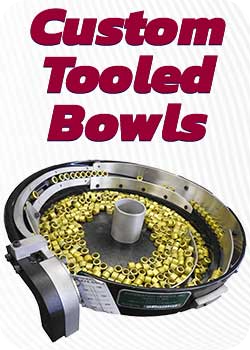

Benefits to Stainless Steel:

- More durable than aluminum

- FDA approved

- Cleaner than aluminum

- More versatile for welding and custom tooling

Benefits to Cast Aluminum:

- Low-cost alternative to stainless

- Quick delivery

- Adequate for simple parts

- Ideal for mass production

- ADI can cast tooling

Amplitude Stickers & Accurate Amplitude Rate

Amplitude stickers give customers a feeder's amplitude rate to determine the most efficient feed rate. View the Amplitude Sticker Diagram listed in the resources below.

Vibratory Feeder Bowl Resources