Vibratory Feeder Bowl Design for Automation

A small design change in a product or assembly part can make all the difference in the success and economic feasibility of an automation project. Often, products are designed without considering automation, particularly vibratory parts feeding.

A small design change in a product or assembly part can make all the difference in the success and economic feasibility of an automation project. Often, products are designed without considering automation, particularly vibratory parts feeding.

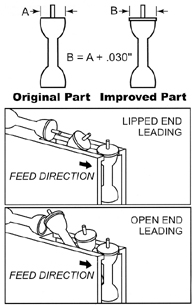

When tooling is not able to distinguish a product's orientation due to either symmetry lack of characteristics, consider making a small change in the part. The drawing below illustrates an actual case where this principle was applied. The initial cost to modify the part was more than offset by the savings in the tooling cost. Inexpensive parts feeders replaced the slow and more costly

Adding a lip to the closed end of this part resulted in less costly and more efficient feeding.

Vibratory Feeder Bowls Contact Us