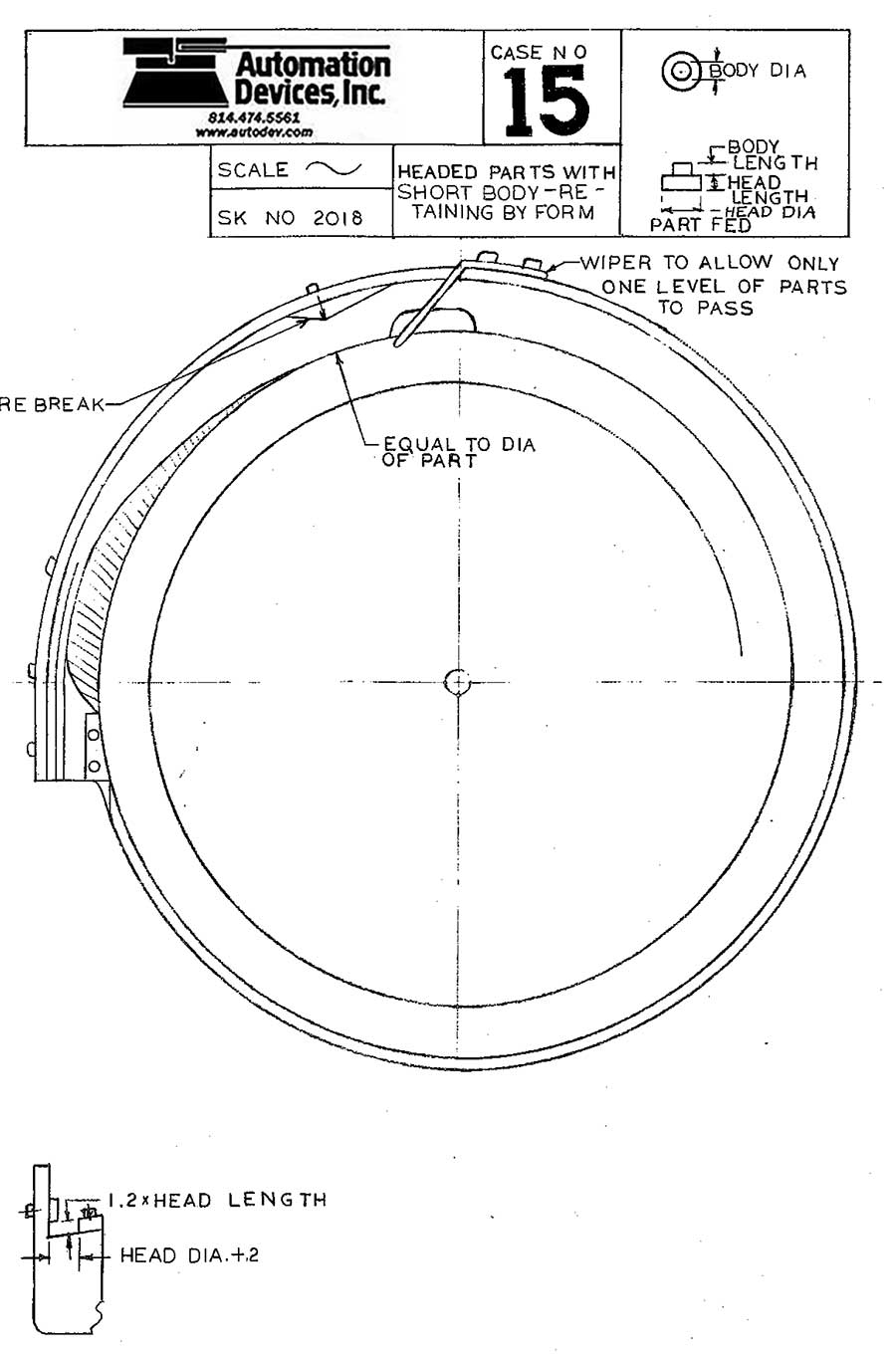

Bowl Tooling Techniques - Case 15

Peg Part

(large diameter base and small diameter body)

End Orientation - Part traveling random diameter to diameter, small diameter body up, large diameter base down

For use with flat track bowls such as:

8" - CB 151 or CB150 on Model 5 Base Unit

11" - CB 274 or CB 273 on Model 8 Base Unit

18" - CB 154 or CB 152 on Model 10 Base Unit

24" - CB 168 or CB 167 on Model 15 Base Unit

Note: Flat track bowls generally have a 7 degree positive rake to allow parts to find the corner of the track and sidewall of the bowl.

Orientation Sequence

Parts are allowed to travel up the bowl helix randomly until they reach a wiper to clear doubles and parts lying on their sides. This wiper is formed to progressively wipe up to prevent parts wedging underneath the wiper. This wiper does most of the work, rejecting misoriented parts. A spill-off directly under the wiper helps the rejected parts return to the bowl center easier and faster. An optional pressure break wedge is installed to relieve downstream congestion of parts. A long gradual spill-off is introduced that increasingly gets deeper toward the outside bowl wall. As the spill-off approaches the sidewall of the bowl, a vertical cover captures only the larger diameter base of the part. The smaller vertical diameter body of the part is allowed to remain uncovered but leans against the side of the vertical cover due to the 7 degree positive rake of the bowl track. At this point, the part is only half supported underneath, while gravity at 7 degrees barely holds the oriented part under the cover for a short span. Only correctly oriented parts may continue to the fully contained tooling at the bowl discharge.