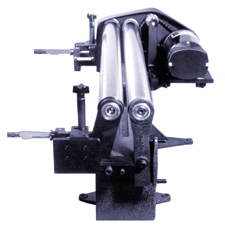

Orienting Roller Description and Features

Orienting Rolls effectively orient and convey parts in a quiet and gentle non-vibratory manner. Increased spacing between parts is often achieved, lending itself to other applications where parts are inspected or gauged.

Each roller is precision ground and hard chrome plated. Optional coatings can be applied to orienting rolls for special applications such as handling food or pharmaceutical items. Abrasion-resistant coatings may also be applied to the rollers.

Orienting Rolls are driven from a gear-reduced motor by way of an O-ring type belt. The belt rides over pulleys, causing one roller to rotate clockwise and the other counterclockwise. This action breaks the friction between the parts and the rollers. The rollers are set at a slight angle so the parts flow downward and away from the point where they are dropped onto the rollers.

Features and Options

Custom-fitted micrometer adjusters permit a quick and accurate changeover to the next part. This system also features a 0-2500 RPM variable speed motor.

Features:

- Precision-ground, case-hardened rolls

- Gear-reduced motors on stock rolls

Options are quoted upon request and include:

- Variable speed motors and controllers

- Abrasion-resistant roll coatings

- Micrometer style

roll gap adjustments - 240 VAC and/or 50 Hz operation

Model 7800

Orienting Roll Models

| Model Number | Roller Length (Inches) |

Motor Speed (RPM) |

Input Voltage | Input Current |

|

7600F

|

12 | 0-2500 Variable | 120 VAC | |

| 1.80 A | ||||

|

7700F

|

18 | 0-2500 Variable | 120 VAC | |

| 1.80 A | ||||

|

7800F

|

24 | 0-2500 Variable | 120 VAC | |

| 1.80 A | ||||

Note: 240 VAC Models are quoted upon request **Users will need a 4590 Controller if using DC input

View All Orienting Rolls Contact Us