Ring Jet Air Amplifiers

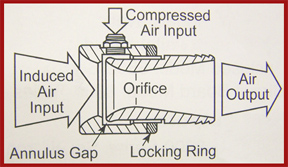

Ring-Jets are three piece mechanical devices which induce a flow of air through a tube without obstructing the tube in any way. They can be utilized in the conveying of material and parts, dust, fumes, etc., which do not respond to conventional pressure or vacuum systems. The adjustable air jets are designed to take in low-volume shop air, amplify it and direct the significantly increased volume through the internal bore of the device. (See illustration below.)

How does a Ring Jet Amplifier work?

Ring-Jets induce a flow of air (Induced Air Input) or gas through an orifice by utilizing a partial vacuum created by an accelerated air flow of pressurized shop air (60 psi minimum) passing through an annular gap. This partial vacuum is due to the Coanda Effect and it causes up to 20 times the volume of Compressed Air to be induced through the orifice.

The output air flow rate can be precisely controlled by varying either the pressure level of the Compressed Air Input or by adjusting the Ring-Jet's Annulus Gap. When a sufficient vacuum is created to increase the volume flow of Induced Air Input, the Air Output flow increases up to twenty times the volume of the shop air passing through the Compressed Air Input.

There is no impeller or other devices to restrict the flow of material through the center of the Ring-Jet. In fact, the Ring-Jet has no moving parts; thus, there is no need for maintenance. The seven stock units are aluminum. Ring-Jets are available in larger bore diameters and in the following materials: brass, stainless steel, mild steel, PVC, and nylon.

Ring-Jet Model Selection Table

| Model Number | Orifice Diameter MM (IN) | Inlet Air Flow (SCFM) | Output Air Flow (SCFM) | Ouput Tube Length (MAX) | A | B | C | D | E |

| Bore Diameter (Inches) | Outside Diameter (Inches) | Overall Length | Air Inlet (NPT) | Output Tube I.D. (Inches) | |||||

|

8306

|

06 (1/4) | 4 | 130 | 20 ft. | 1/4 | 1 | 2 1/2 | 1/8" MPT | 3/4 |

|

8312

|

12 (1/2) | 6 | 200 | 20 ft. | 1/2 | 1 | 2 1/2 | 1/8" MPT | 3/4 |

|

8320

|

20 (3/4) | 10 | 240 | 25 ft. | 3/4 | 1 1/2 | 2 1/2 | 1/8" MPT | 1 1/4 |

|

8325

|

25 (1) | 14 | 400 | 30 ft. | 1 | 2 | 3 1/2 | 1/4" MPT | 1 1/2 |

|

8340

|

40 (1 1/2) | 18 | 500 | 30 ft. | 1 1/2 | 2 1/2 | 3 3/4 | 1/4" MPT | 2 |

|

8350

|

50 (2) | 34 | 730 | 30 ft. | 2 | 3 1/2 | 5 1/4 | 1/4" MPT | 3 |

|

8375

|

75 (3) | 85 | 2000 | 30 ft. | 3 | 5 1/4 | 6 5/8 | 1/2" MPT | 4 |

Ring-Jet Applications

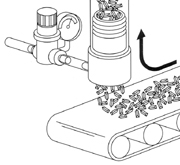

Conveying

- Load overhead storage hoppers from supply boxes on the floor.

- Transfer finished materials to bulk storage.

- Remove waste from material exiting a punch press.

- Spray flocking materials.

Cleaning Air

- Remove smoke, dust, and fumes from welding areas.

- Exhaust paper and fabric dust from cutting rooms.

- Freshen the air in poorly ventilated work areas.

Drying

- Remove water vapor from cans entering a filling station.

- Reduce paint drying time to accelerate production.

Cooling

- Harden molded food products such as chocolate.

- Rapidly reduce the temperature of injection molded plastic parts.

View All Orienting Devices Contact Us