Vibratory Feeder Part Orientation

Orientation is defined as controlling the attitude of parts so that they are in the correct position when they arrive at a designated work or assembly station

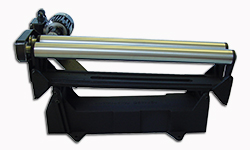

This is normally done by passing the parts through a series of engineered obstructions or guides in the bowl track, commonly referred to as tooling. However, out-of-bowl aids such as Orienting Rolls and Feeder Tracks may also be used to orient headed or tapered parts, or to inverted parts 180° prior to reaching the workstation.

Feeding characteristics and the orientation of certain parts can be seriously affected by overloading the feeder bowl. For instance, washers normally feed radius-to-radius, but will feed face-to-face in an undesirable pattern if too many are in the bowl.

Pneumatic air jets, used in an efficient manner, can assist in orienting parts and in increasing the number of oriented parts which reach the discharge of the bowl. They are frequently used to reject non-oriented parts, to separate parts, or to tip parts as they enter a discharge chute.

NOTE: For best performance, include in the design an automatic auxiliary supply hopper and a level control switch to keep a predetermined level of parts in the feeder bowl