Orienting Various Part Shapes with Tooling - Cylindrical Parts

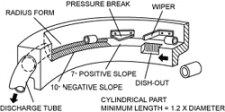

Cylindrical Parts - Length Greater than Diameter

These parts have a natural tendency to feed on their sides. Select a bowl having a 7° positive track. About 90° from the bowl discharge, install a wiper to permit one level of parts to pass under. Dish out the track under the wiper to allow one row to pass. Install a pressure break so that only one part at a time can move around it. Machine a circular groove to fit the part diameter and add a 10° negative slope on the inner edge of the track - parts not in the groove will return to the bowl.

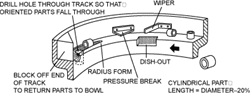

Cylindrical Parts - Length Equal to Diameter

These parts may travel on their side or on their end. Select a bowl having a 7° positive track. Insert a pressure break and a wiper, and machine a dish-out. Machine a circular groove in the last 30° of track and drill a hole through the track. The groove orients parts onto their sides. At the drilled hole, they tip 90° and drop through.