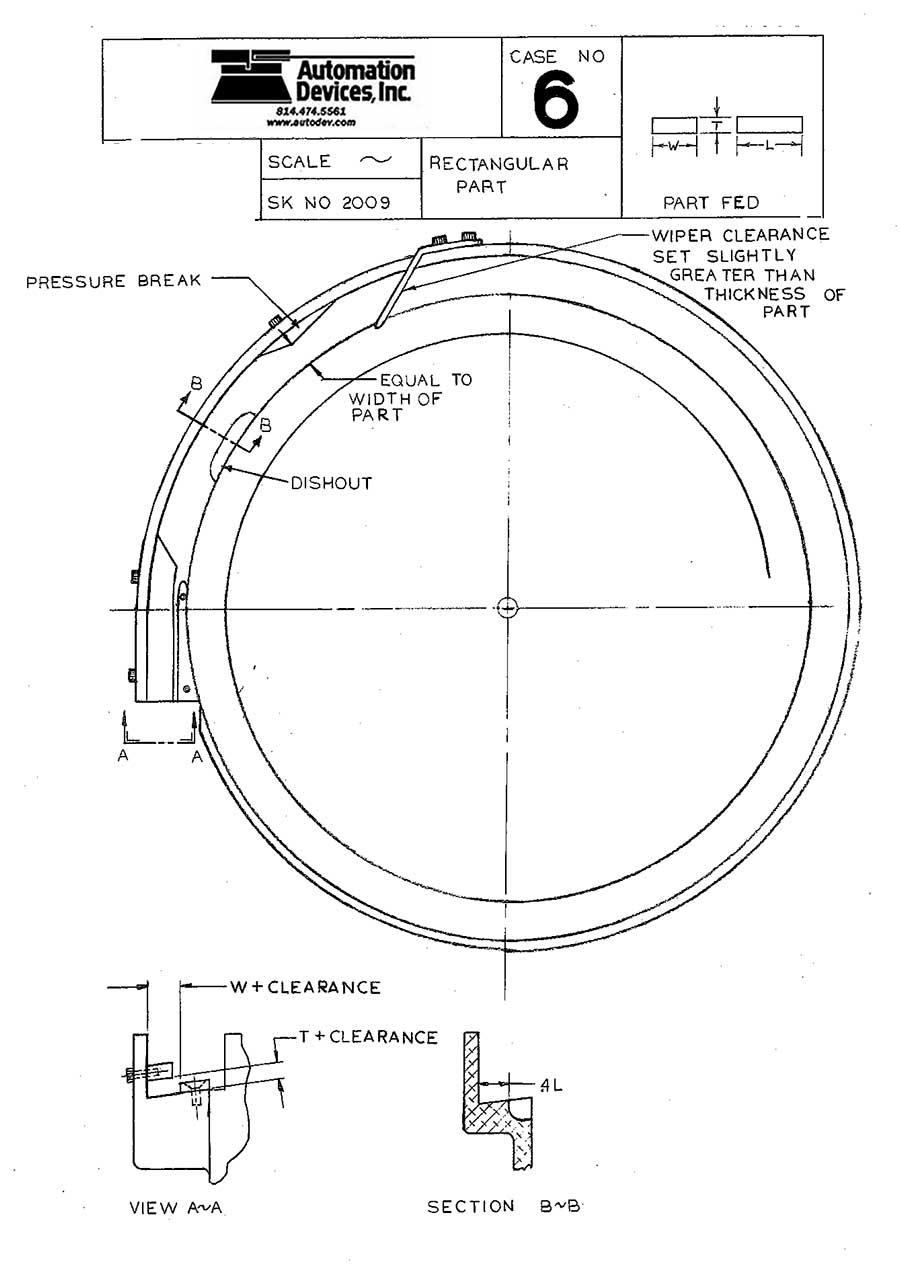

Bowl Tooling Techniques Case 6

Rectangular Part

End Orientation - Random End to End, Part Lying Flat and Traveling Longitudinally

For use with flat track bowls such as:

8" - CB 151 or CB150 on Model 5 Base Unit

11" - CB 274 or CB 273 on Model 8 Base Unit

18" - CB 154 or CB 152 on Model 10 Base Unit

24" - CB 168 or CB 167 on Model 15 Base Unit

Note: Flat track bowls generally have a 7 degree positive rake to allow parts to find the corner of the track and sidewall of the bowl.

Orientation Sequence

All tooling can be completed in the last quadrant of the bowl. Parts will climb the bowl helix randomly until a wiper brings them to one layer. A shallow pressure break will relieve any back pressure downstream through the tooling. A dish-out/spill-off will reject all parts that are traveling side by side and allow parts traveling longitudinally to pass due to a "point of balance". Once the parts pass the spill-off area, they will be correctly oriented and can be contained on the top and side, maintaining its orientation for the next operation.