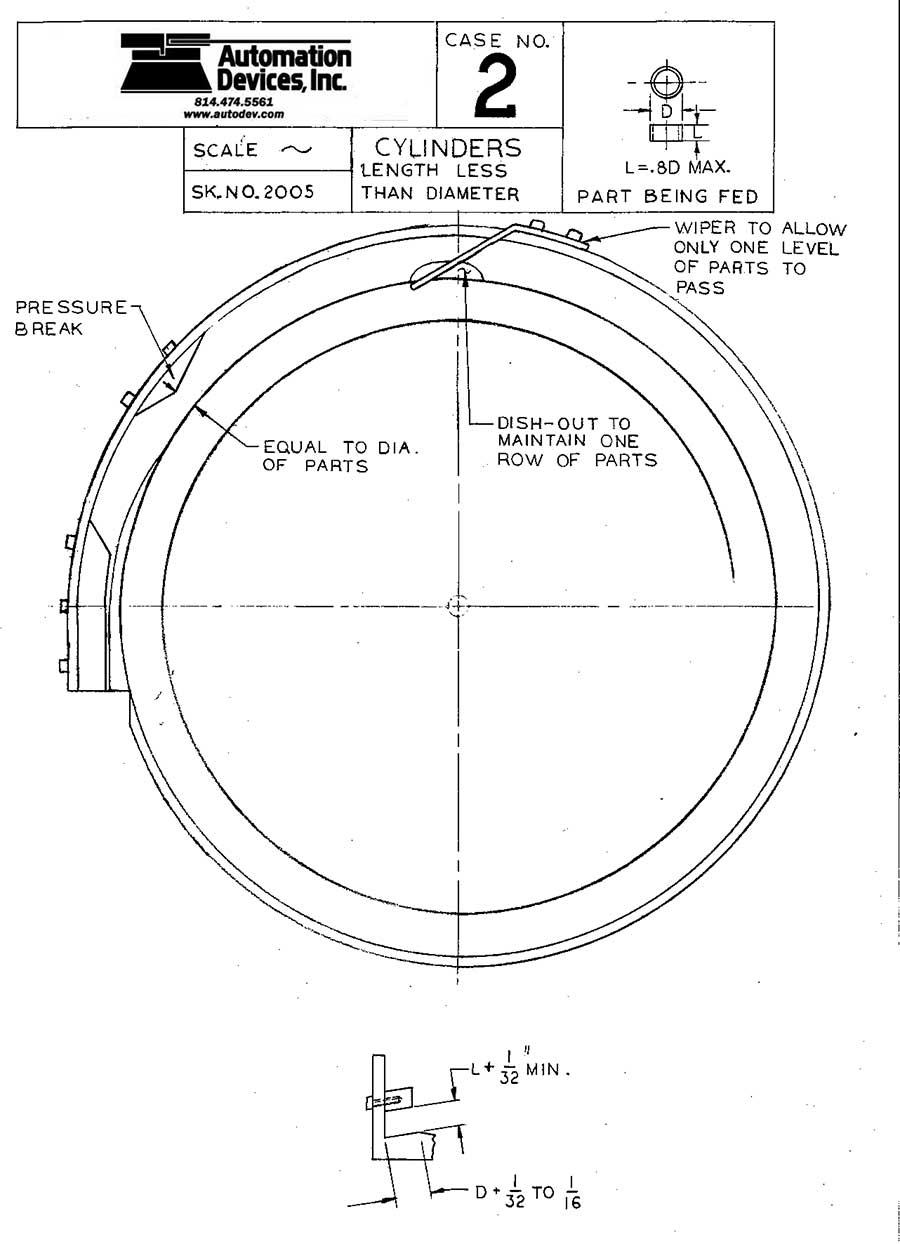

Bowl Tooling Techniques - Case 2

Cylindrical Part - Diameter Greater Than Length

End Orientation - Random Diameter to Diameter, Centerline Axis Vertical

For use with flat track bowls such as:

8" - CB 151 or CB150 on Model 5 Base Unit

11" - CB 274 or CB 273 on Model 8 Base Unit

18" - CB 154 or CB 152 on Model 10 Base Unit

24" - CB 168 or CB 167 on Model 15 Base Unit

Note: Flat track bowls generally have a 7 degree positive rake to allow parts to find the corner of the track and sidewall of the bowl.

Orientation Sequence

Part completes more than one complete revolution in random orientation. The goal is to reject or convert all parts that are not diameter to diameter, centerline axis vertical. As parts approach the first wiper, rolling parts and doubles are returned to the center of the bowl. Only parts that are centerline axis vertical may pass. A pressure break reduces the build - up pressure in the bowl and diverts all parts back into the bowl when the bowl feed rate exceeds what the next operation beyond the feeder bowl can accept. At the bowl discharge point, a cover is fabricated to contain and control four or five parts to allow a smooth transition to the next operation.