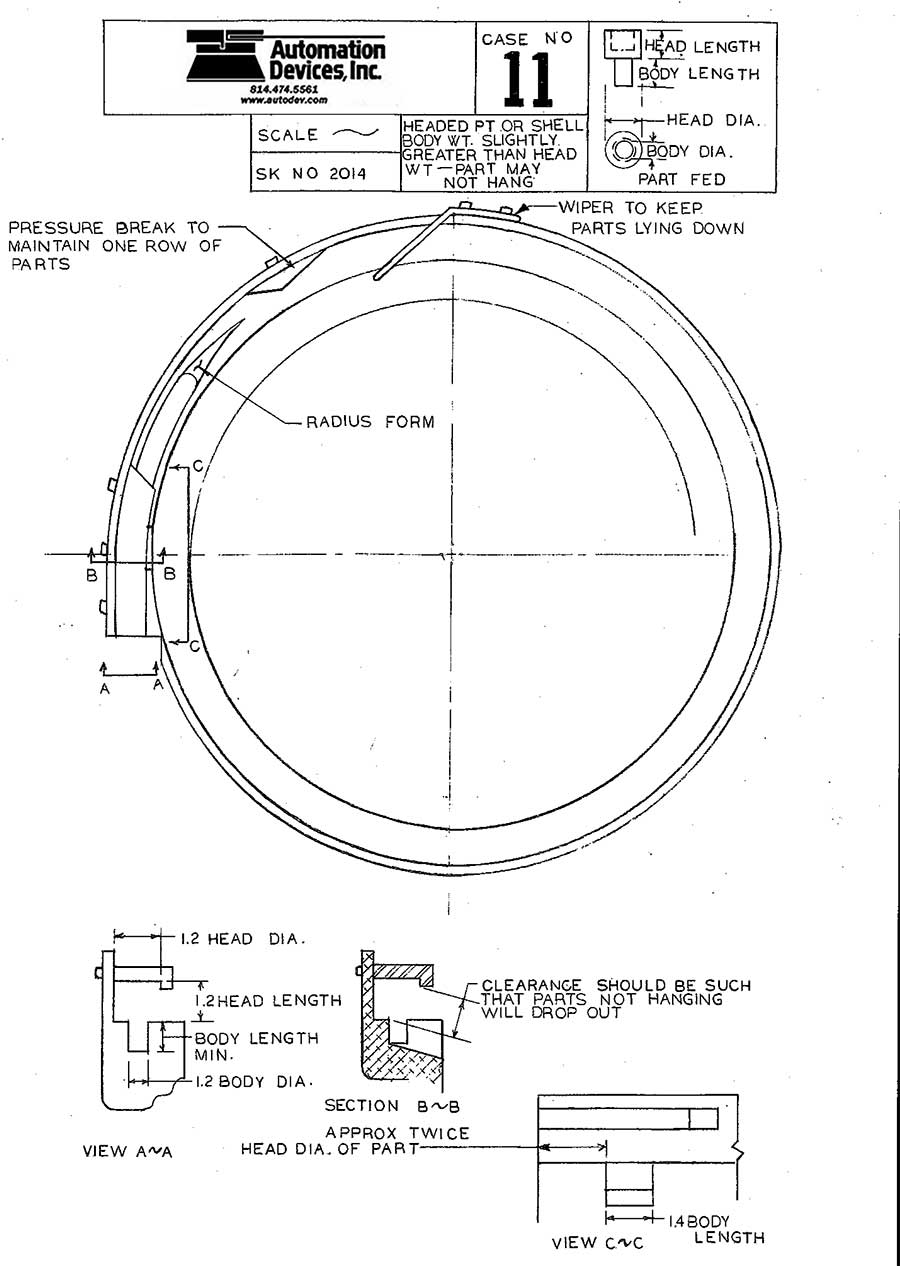

Bowl Tooling Techniques - Case 11

Headed Part (body weight is greater than head weight)

End Orientation - Part traveling side by side, larger diameter head up, centerline axis vertical

For use with flat track bowls such as:

8" - CB 151 or CB150 on Model 5 Base Unit

11" - CB 274 or CB 273 on Model 8 Base Unit

18" - CB 154 or CB 152 on Model 10 Base Unit

24" - CB 168 or CB 167 on Model 15 Base Unit

Note: Flat track bowls generally have a 7 degree positive rake to allow parts to find the corner of the track and sidewall of the bowl.

Orientation Sequence

Parts are allowed to travel up the bowl helix randomly until they reach the last quadrant of the bowl. A wiper is the first piece of tooling to knock parts standing on their head over. A pressure break wedge allows the overflow parts to return to the bowl while allowing a single line of parts to enter a shallow linear groove. Too many parts in the groove decreases the feed rate and increases the rejection rate. This groove section pre-aligns the parts linearly, assisting in the next orienting sequence, which is the hang sequence. Parts traveling with the head leading and trailing will both hang in the machined square groove. A cover is positioned overhead to contain oriented parts. A spill-off is machined at the midpoint of the cover to reject misoriented parts back into the bowl. Due to the relief granted by the spill-off and the pressure break, this tooling technique allows the bowl to run under back pressure and does not require electronic back pressure control.