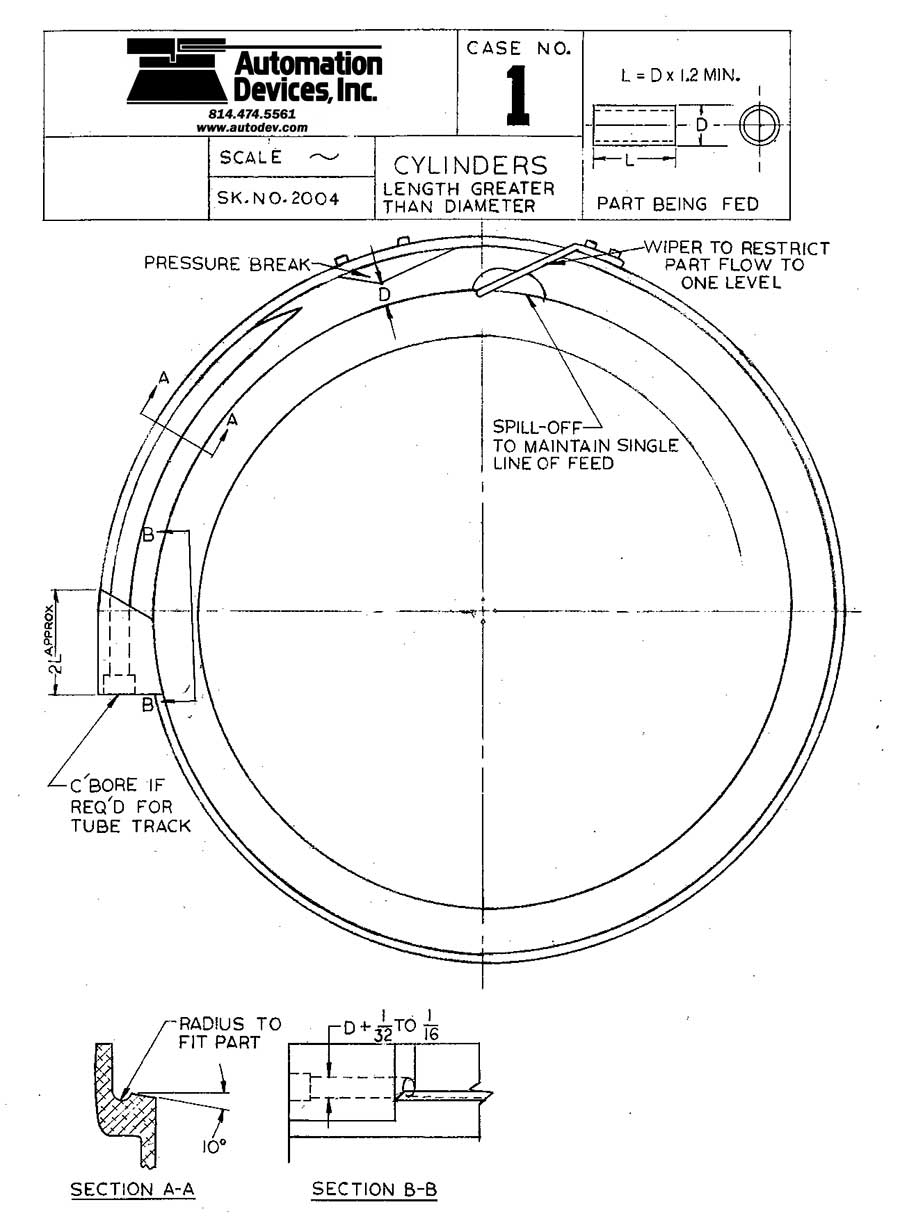

Bowl Tooling Techniques - Case 1

Cylindrical Part - Length Greater Than Diameter

For use with flat track bowls such as:

8" - CB 151 or CB15 on Model 5 Base Unit

11" - CB 274 or CB 273 on Model 8 Base Unit

18" - CB 154 or CB 152 on Model 10 Base Unit

24" - CB 168 or CB 167 on Model 15 Base Unit

Orientation Sequence

Part completes one full revolution in random orientation. Most tooling will be done in the last quadrant of the bowl. Part is brought to a single line of feed through the use of a wiper to knock standing parts down or rejecting doubles. At the same time, a spill off rejects parts that are not traveling linearly. Next, a pressure break allows a single part to pass around the ramp and drift back to the corner cradle of the bowl sidewall. If the parts are running under backpressure, the parts will be diverted back into the bowl at the pressure break. A groove can be machined into the bowl track slightly larger than the diameter of the part to contain and control the part into a machined block that will capture the part on top and bottom which will bolt to the bowl discharge. A counter bore can be machined into the block if a tube will be used to convey the part through gravity to the next operation.