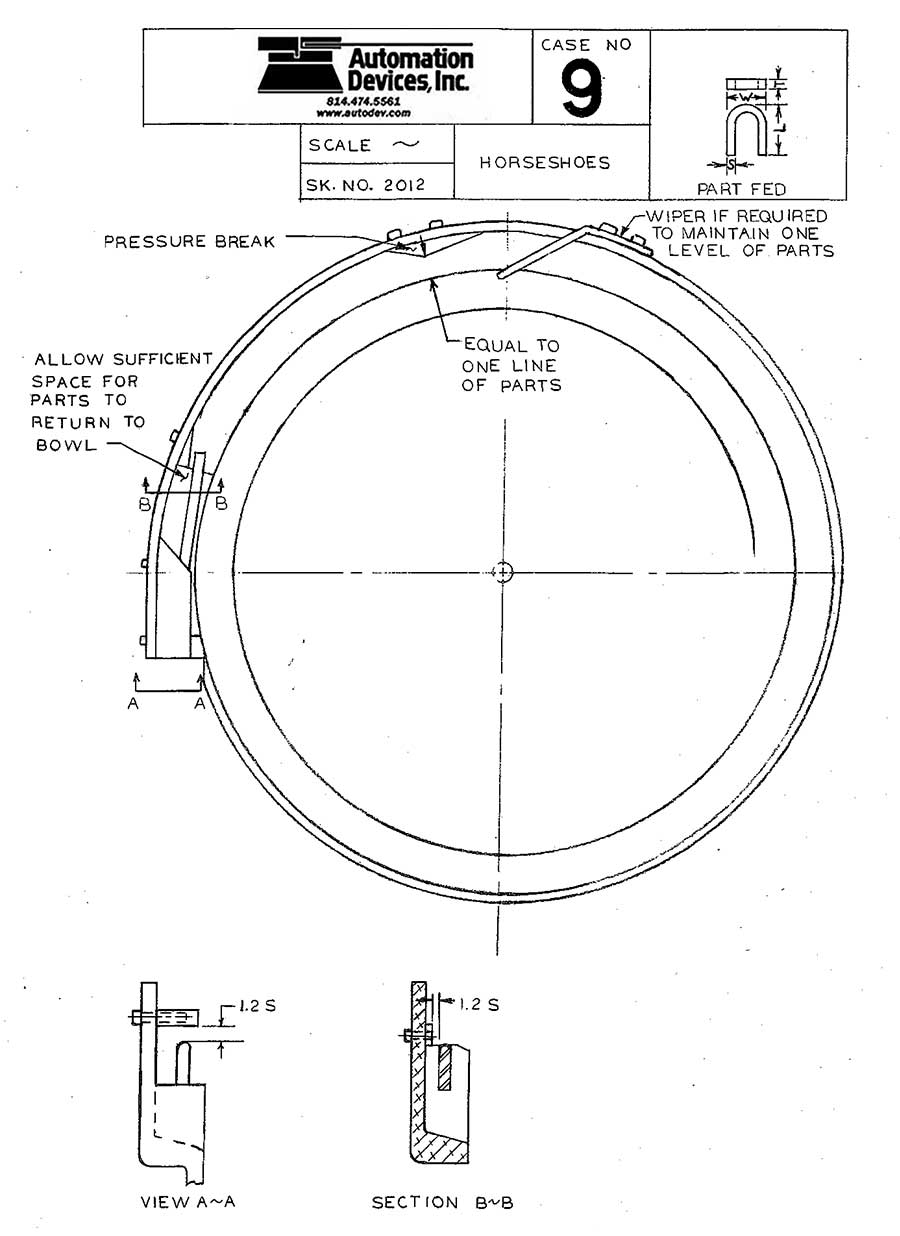

Bowl Tooling Techniques - Case 9

Horseshoe Shaped Part

End Orientation - Part traveling linearly back to back, hanging with the open end of the "U" down

For use with flat track bowls such as:

8" - CB 151 or CB150 on Model 5 Base Unit

11" - CB 274 or CB 273 on Model 8 Base Unit

18" - CB 154 or CB 152 on Model 10 Base Unit

24" - CB 168 or CB 167 on Model 15 Base Unit

Note: Flat track bowls generally have a 7 degree positive rake to allow parts to find the corner of the track and sidewall of the bowl.

Orientation Sequence

Parts are allowed to travel up the bowl helix randomly until they reach the last full quadrant of the bowl. A wiper is installed to allow only one level of parts to pass. A pressure break wedge can be installed to thin parts even further and relieve back pressure in downstream tooling. A "pocket" can be machined in the bowl with a single rail "bridge" spanning the pocket to allow parts to start across the bridge and hang with the open end down. The pocket should be machined deep enough to allow enough space for correctly oriented parts to hang and allow misoriented parts to pass under the legs of the hanging parts. Parts that don't hang will spill into the pocket on either side of the bridge rail and return to the bottom of the bowl. Once hanging parts are settled on the rail, a cover can be introduced to contain the part and eliminate any overlap. The pocket should be terminated under the cover and the floor of the bowl track brought back under the part legs to increase part control and part drive for better transferability into the next operation.