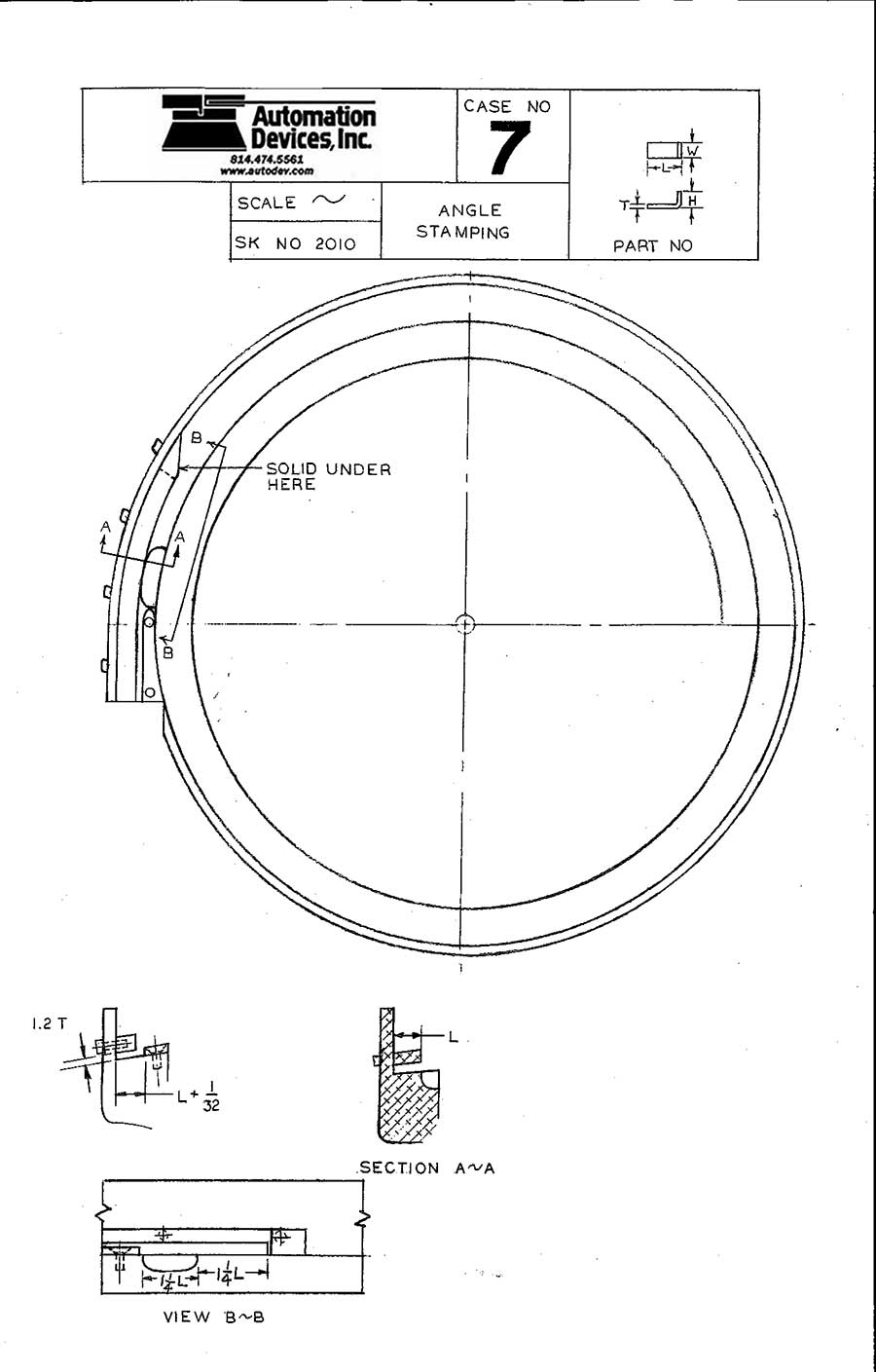

Bowl Tooling Techniques - Case 7

90 Degree Angle Stamping

End Orientation - Part Traveling Side By Side, Lying Flat With 90 Degree Tab Up and Toward Bowl Center

For use with flat track bowls such as:

8" - CB 151 or CB150 on Model 5 Base Unit

11" - CB 274 or CB 273 on Model 8 Base Unit

18" - CB 154 or CB 152 on Model 10 Base Unit

24" - CB 168 or CB 167 on Model 15 Base Unit

Note: Flat track bowls generally have a 7 degree positive rake to allow parts to find the corner of the track and sidewall of the bowl.

Orientation Sequence

Parts are allowed to travel up the bowl helix randomly until they reach the last several inches of the bowl. A formed cover is fabricated with a wedge - shaped angle on the leading edge of the cover to wipe off any mis - oriented parts. Parts that are lying flat with the tab up will find their way under the cover, taking advantage of the 7 degree positive rake of the bowl track which, through gravity and vibration, will let the longer leg of the stamping to swing away from the bowl center under the cover. Parts not securely under the cover will tip off the track due to the dish - out/ spill - off. Once the parts pass by the spill - off, they will all be side - by - side with the 90 degree tab up. A guard can now be installed on the outside of the 90 degree bended tab to fully contain the part and transfer it to the next operation.