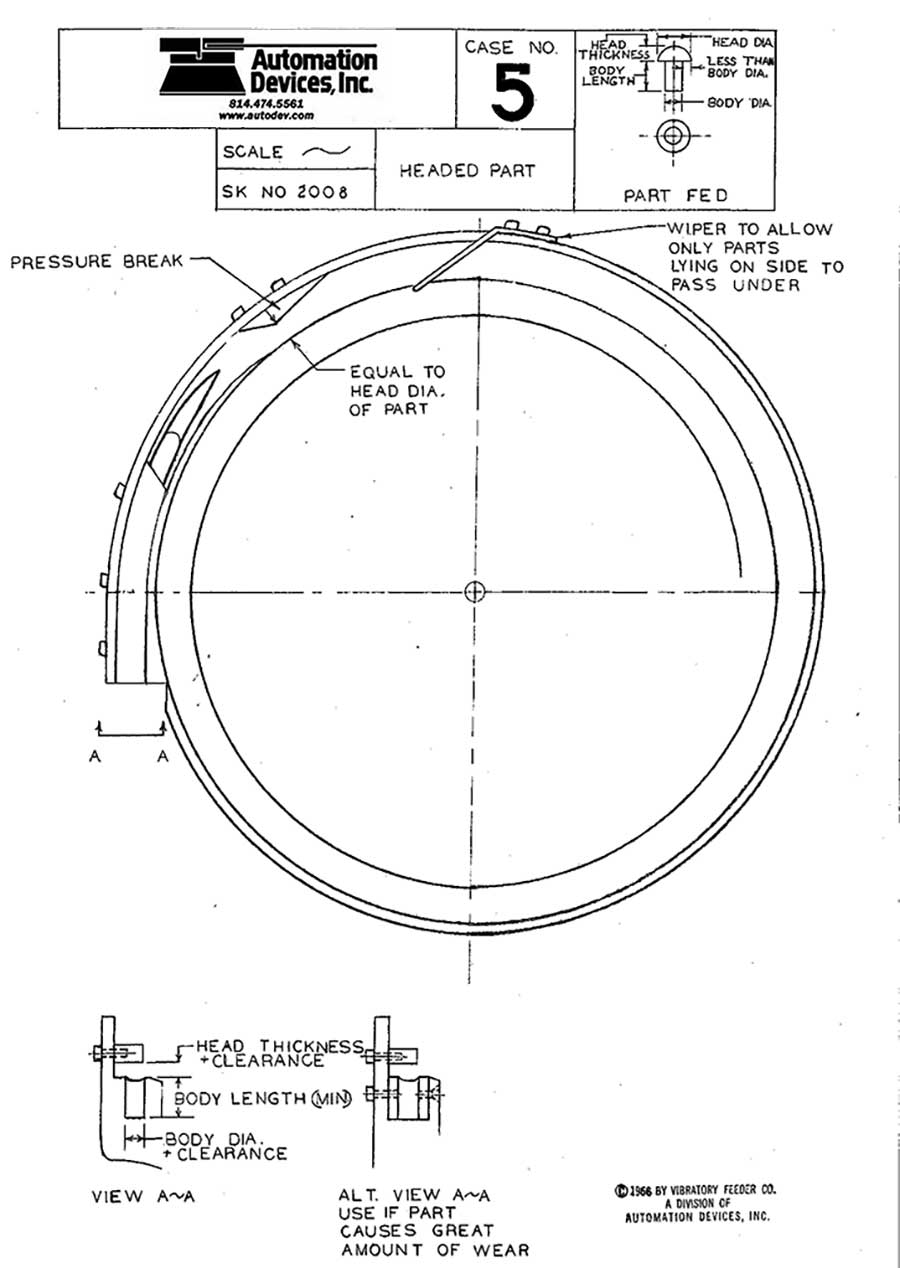

Bowl Tooling Techniques - Case 5

Headed Part

End Orientation - Random Diameter to Diameter, Centerline Axis Vertical, Hanging by Larger Diameter

For use with flat track bowls such as:

8" - CB 151 or CB150 on Model 5 Base Unit

11" - CB 274 or CB 273 on Model 8 Base Unit

18" - CB 154 or CB 152 on Model 10 Base Unit

24" - CB 168 or CB 167 on Model 15 Base Unit

Note: Flat track bowls generally have a 7 degree positive rake to allow parts to find the corner of the track and sidewall of the bowl.

Orientation Sequence

Parts are free to travel up the bowl helix randomly until the final quadrant. A wiper will initially knock doubles and standing parts back into the bowl center, allowing only parts lying down to pass. A triangular pressure break can be installed next to relieve a part pile up from static parts waiting to exit the bowl. A radius in the bowl track prior to the hanging section allows the parts to align themselves for a linear swing from horizontal to vertical hanging from the head between two parallel steel rails mounted on both sides of a machined groove at the bowl discharge. This hanging section should include a top cover once the part settles into a hanging orientation.