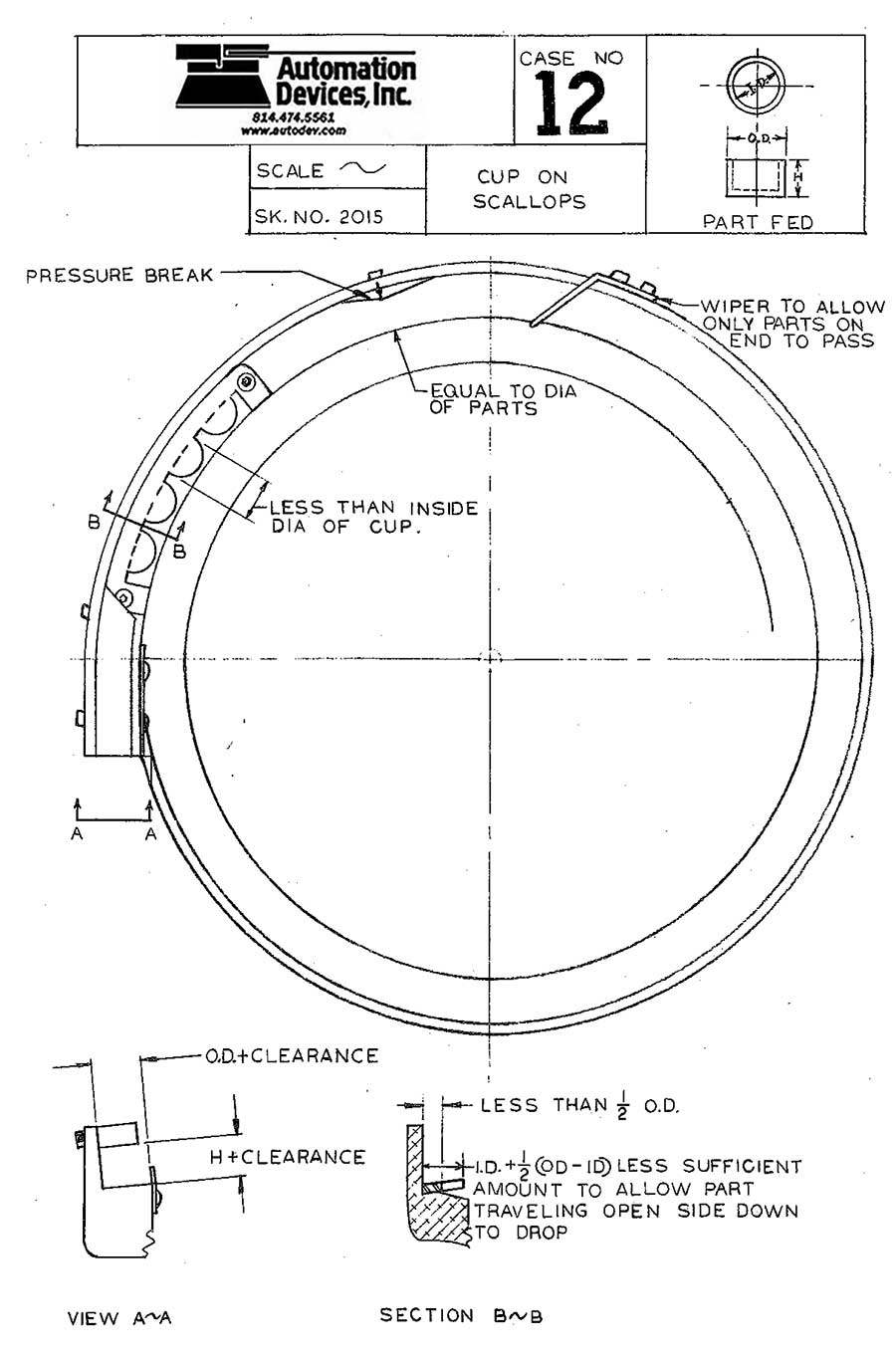

Bowl Tooling Techniques - Case 12

Cup and Cap Shaped Parts

End Orientation - Part traveling random diameter to diameter, centerline axis vertical, open side up

For use with flat track bowls such as:

8" - CB 151 or CB150 on Model 5 Base Unit

11" - CB 274 or CB 273 on Model 8 Base Unit

18" - CB 154 or CB 152 on Model 10 Base Unit

24" - CB 168 or CB 167 on Model 15 Base Unit

Note: Flat track bowls generally have a 7 degree positive rake to allow parts to find the corner of the track and sidewall of the bowl.

Orientation Sequence

Parts are allowed to travel up the bowl helix randomly until they reach a wiper to clear any parts not lying flat. A pressure break is installed to relieve pressure on downstream tooling. The bowl track is partially machined away, simulating a spill-off, making room for installation of scallops. While machining the spill-off, it is ok to break through to the outside of the bowl. A small piece of stainless steel can be installed as a tray later if necessary. The scallops are constructed to utilize the inner diameter of the cup or cap's open side. A cup with the open side up will skip across the scallops while a cup with the open side down will drop onto the scallop lobe and slide back into the bowl center. Several scallops are constructed in a row to allow multiple rejection points, decreasing the possibility of a misoriented part passing by. Once the cup with open side up traverses the scallops, it can be controlled and contained via a cover on top and on the side.