Pan Feeder Hoppers

Automation Devices combines superior resources with 55 years of experience to build hoppers and pan feeders known for quality and reliability. We maintain ample inventory of more than 15 different models ensuring rapid delivery times while maintaining flexibility to serve a variety of industries. Our hoppers and feeders can be used in a variety of situations from general purpose to being suited to meet exacting FDA standards.

ADI hoppers and pan feeders are designed to reduce the total weight of parts in a vibratory feeder bowl and maintain an optimal flow of material or parts. The utilization of a hopper greatly reduces wear and maintenance on a feeder while amplifying feed rate.

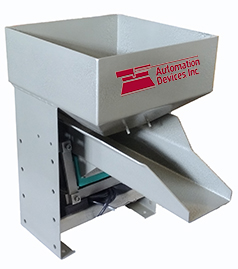

Standard Pan Feeder Hopper Mild Steel and Painted

Pan Feeder Features:

- Mild Steel Construction

- 11 and 12 gauge sheet metal

- Food grade and FDA approved available

- Integral welded fabrication

- Easy mounting and height adjustment (when using optional stands)

- Anti-Jamming Design

- Painted

The pan's shape keeps parts from going over the sides and also precludes the possibility of parts jamming between the pan and the bin's discharge funnel.

Applications

The Pan Feeder Hopper conveniently provides extra parts storage and serves as a bulk delivery system to maintain a proper parts level in a feeder bowl. Innovative systems designers have expanded the use of a Feeder Hopper to include parts delivery to packaging stations and to convey bulk materials. A hopper serves any application where a storage requirement is coupled with a need to convey a product to processing equipment.

Model 5500S Description

The Model 5500S Pan Feeder Hopper is a stationary bin with a vibratory pan feeder mounted under the bin's discharge funnel. Parts are gravity fed down the discharge funnel and onto the vibrating pan, where they are conveyed to the pan's discharge. Parts drop off the end of the pan and into devices such as vibratory feeder bowls.

Pan Feeder Hoppers store parts and deliver those parts to other devices on demand. During a portion of the electrical cycle, power is applied to the electromagnet. When energized, the electromagnet pulls back and down on the armature which is attached to the pan assembly. When the electromagnet becomes de-energized during the second half of the electrical cycle, the armature and pan are released and spring forward and up. The pan assembly is mounted on leaf-type springs which allow the pan to move in a back-and-downward motion (power cycle) and in an up-and-forward motion (release cycle). These combined motions cause parts on the pan to move forward until they drop off the pan.

An optional amplitude controller, Model 6000 Series, regulates the amplitude of the pan's vibration, adding a measure of precision to the part delivery rate from the hopper. To prevent the Pan Feeder Hopper from overfilling the using machine, Automation Devices makes the Model 8650 Level Control Switch.

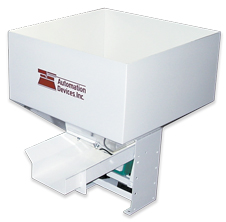

Model 5500BR Description

The 5500BR hopper is ideal for pharmaceutical and food applicaitons. The detactable bin prohibits parts from coming into contact with the springs and feeder mechanisms. It also allows for easy cleaning and quick and uncomplicated reassembly.

Model 5500E Description

The 5500E Pan Feer Hopper has a square sided, vertical column that includes a trough-like design that prevents parts from nesting and tangling. Typical applications include longer parts, such as nails or bolts.

Custom Coated Steel Hopper

Custom Stainless Steel Hopper

5500S Pan Feeder Hopper

5500BR Pharmaceutical Hopper

5500E Straightwall Hopper